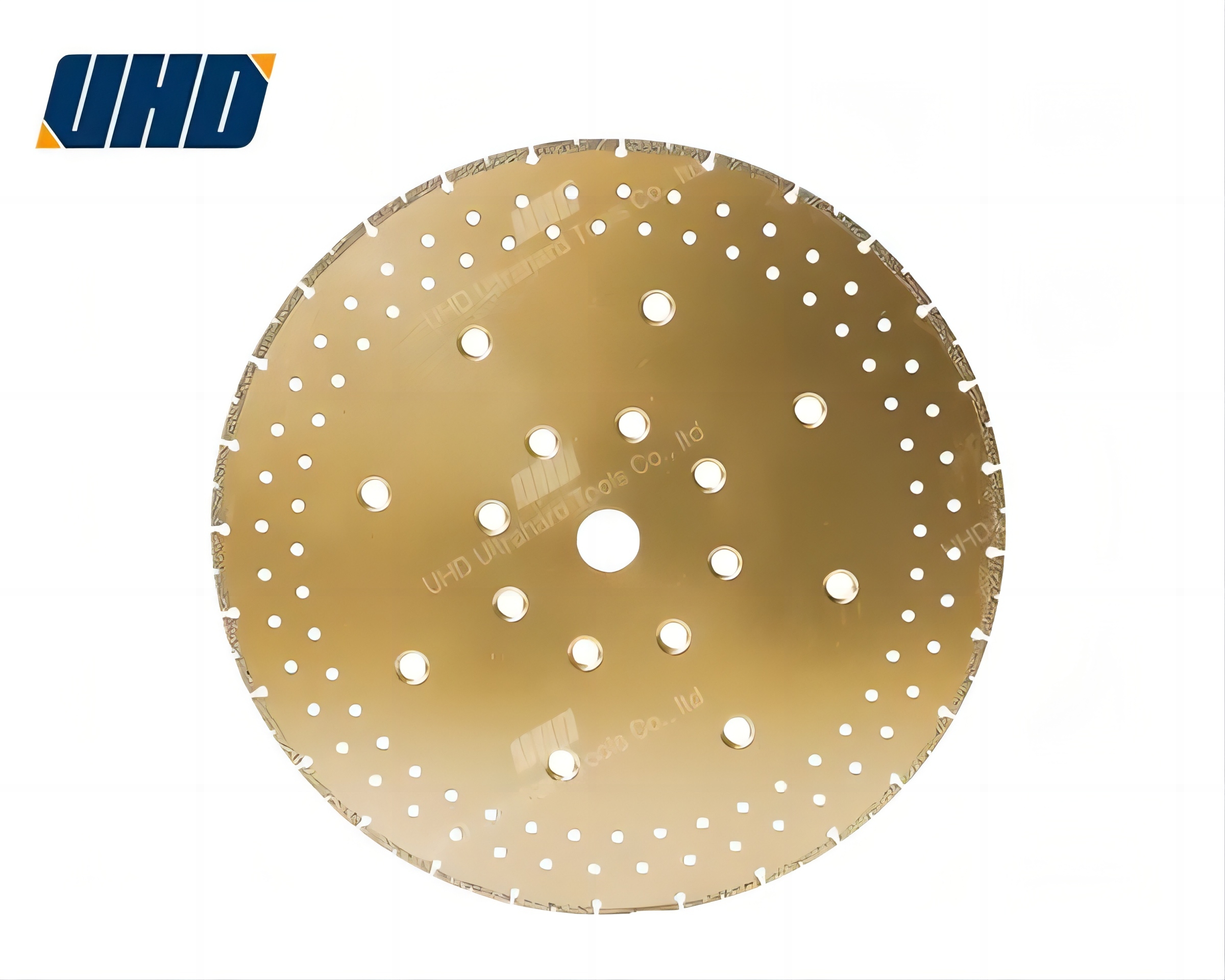

Product Details

Product Introduction

Henan UHD Superhard Materials Tools Co., Ltd. (UHD) specializes in the research, development, and manufacture of industry-leading, ultra-efficient vacuum-brazed diamond cutting saw blades. These blades operate stably in ambient temperatures ranging from 0°C to 120°C and are widely used in the metalworking and stone manufacturing industries. Utilizing an advanced vacuum brazing process, these saw blades offer exceptional wear resistance and durability, significantly improving cutting accuracy and efficiency while helping customers effectively minimize equipment downtime. Leveraging a strong R&D team and in-depth collaboration with Henan University of Technology, UHD ensures that each saw blade meets international standards and can be customized to meet the diverse process requirements of individual customers. Serving the global market through a mature international trade network, we are committed to providing high-quality, one-stop cutting solutions to customers in the metal and stone industries, helping them maintain their competitive edge.

Advantages and features

1. High-efficiency vacuum brazing process ensures the stability of saw blade structure and prolongs its service life.

2. Excellent wear resistance, adaptable to variable working conditions from 0°C to 120°C.

3. Precise cutting performance to ensure high-precision requirements for metal and stone processing.

4. Customized design capabilities to meet the unique process parameters of different customers.

5. Relying on strong R&D capabilities and cooperation with universities, we have leading technology and reliable quality.

6. Global trade support facilitates customers' efficient procurement and logistics services.

Application Scenario

It is suitable for stone processing plants, metal product manufacturers, machining workshops, and building material production industries. It is particularly suitable for professionals and companies that require highly wear-resistant and high-precision cutting solutions. It covers the global metal processing and stone manufacturing markets and meets the diverse cutting process needs.